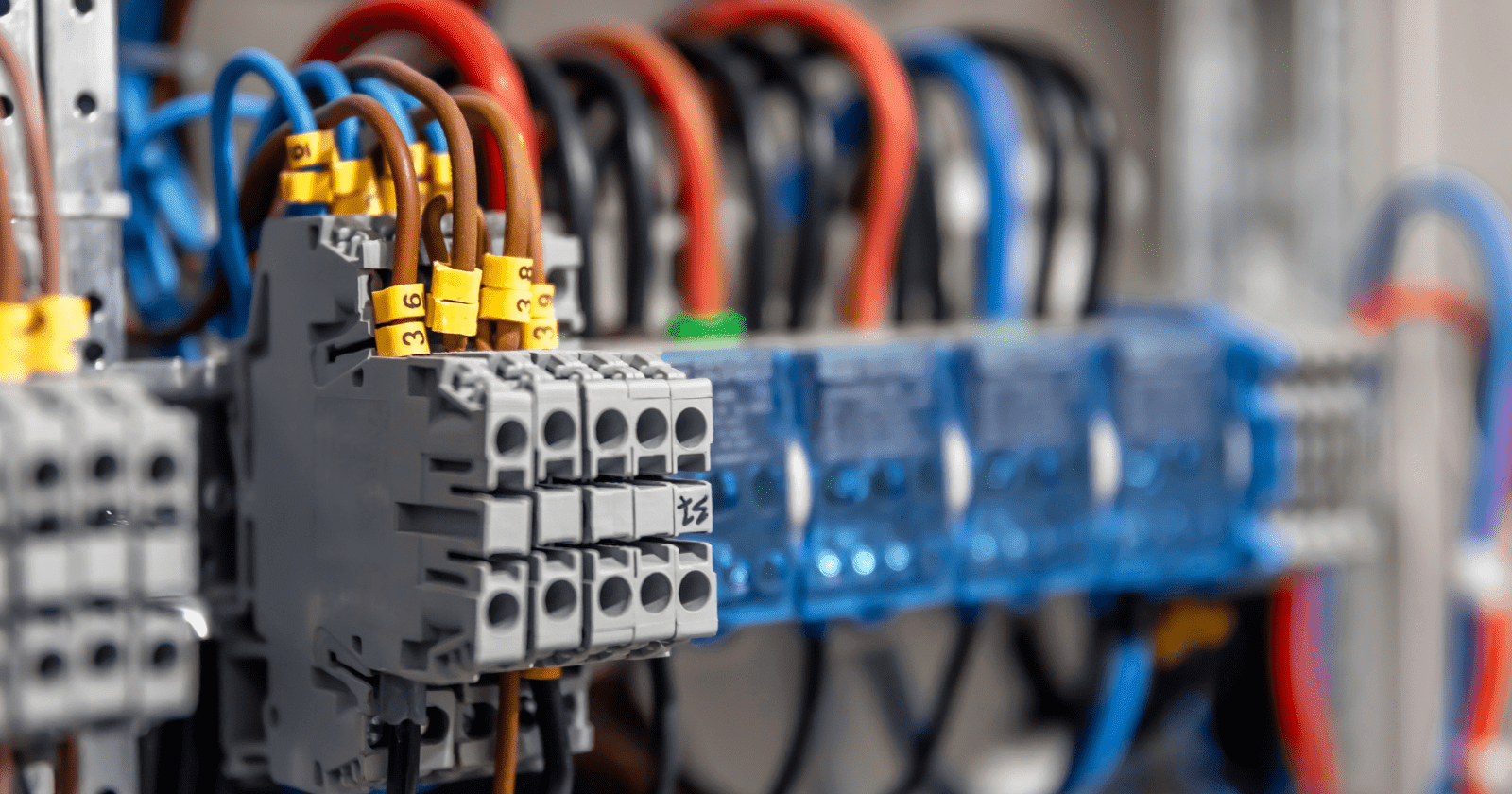

Contactors without overload protection may be used to control: Think of it as a light switch for very demanding electrical work. In essence, it is a contactor. However, contactors are much more powerful than your average household switch, which makes them perfect for managing appliances like heaters, motors, and even whole lighting systems.

Contactors without overload protection may be used to control

The intriguing aspect is that overload protection isn’t usually included into contactors. It may come as a surprise, but there are instances in which having a simpler configuration is preferable.

What then can a contactor regulate without overload protection?

- Lighting Systems: Picture a sizable structure with several lighting zones. Specific parts may be effectively turned on and off using contactors, eliminating the requirement for separate overload protection for each light fixture.

- Consider big ovens or industrial heating systems: when considering resistive heating elements. If the heating element itself has integrated thermal protection, contactors provide a dependable means of turning these high-power loads on and off.

- Pre-protected Motors: A contactor may function as a remote on/off switch to integrate a motor into a larger control system if the motor already has an overload protection circuit installed.

Why not sometimes bypass the overload protection?

- Cost-Effectiveness: Adding overload protection may not be essential for simple applications. Often, a contactor by itself is a more cost-effective option.

- System Design: Overload protection may be taken care of in another area of the circuit in some configurations. The contactor is reduced to a single part of a bigger safety net.

- Space Saving: A contactor’s reduced footprint as compared to a contactor with overload protection might be a considerable benefit, especially with compact control panels.

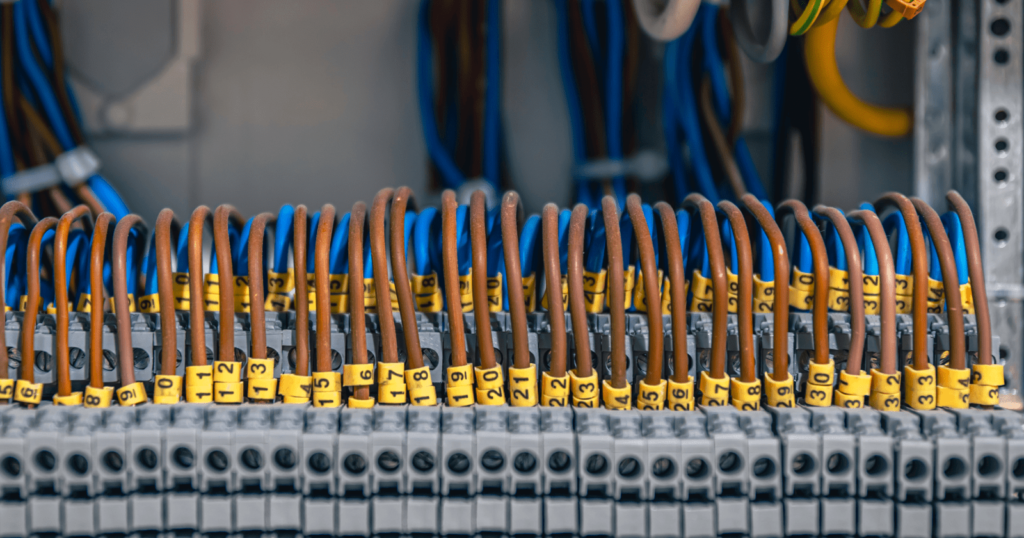

When selecting a control transformer for a specific application

The quiet heroes of electronics, control transformers make sure your gadgets receive the precise amount of power they need. Choosing solution, however, might seem like cracking a code since there are so many to choose from. Do not be alarmed, fellow do-it-yourselfers and tinkerers! You will be able to choose the ideal control transformer for your next project with the help of this guide.

First Step: Recognize Your Needs

- The most important need is voltage: What voltage is required for your gadget to function? Voltages like 12V, 24V, or 48V are provided via common control transformers. To be sure, see the specs for your device.

- Power Consumption: Measured in Volt-Amperes (VA), a device’s “appetite” for power is present. This demand has to be met by a transformer. Check the VA rating of your gadget online or in the handbook.

Step 2: Assessing the Transformer’s Size

- Never descend below: The VA rating of the transformer must always match or exceed the VA consumption of the device. Reduced power supply may cause faults or even damage to the transformer.

- There is excellent headroom: To accommodate for prospective future upgrades or inrush current (a brief spike as the device starts up), consider adding a little buffer, perhaps 20% extra VA.

Step 3: Examining the Add-ons

- Electrical isolation between the main and secondary circuits is provided by an isolation transformer, which adds an additional degree of security, especially for delicate electronics.

- Mounting Options. Does your transformer need to be installed on a wall or will it be hidden within a box? Select a model that has the right mounting components.

- Environmental Factors to Be Considered Is the project intended for a wet environment? In order to avoid corrosion or overheating, look for a transformer rated for such circumstances.

All of the following are considerations when selecting overload relays except the?

Check Your Knowledge Here! Can you identify the outlier? While each of the aforementioned factors is important, motor brand isn’t a direct factor to take into account while choosing overload relays. It is the motor’s current rating and operating characteristics—not its brand name—that the relay must be compatible with.