While you’re tasked with the administration of electrical tools, grasp the importance of exact management inside industrial purposes. Motor management, an intricate a part of industrial management, hinges on the strong shoulders of contactors—a pivotal ingredient in dealing with the excessive calls for of beginning and operating motors. Nevertheless, the eventualities the place you administer contactors with out overload safety demand your sagacity. These particular management contactors adeptly negotiate the influx of preliminary excessive currents throughout motor activation with out inherent safeguards in opposition to potential overload circumstances.

Your function in configuring electrical management with out overload safety is twin; when you should seamless operation, you need to additionally take into account the longevity and security of the equipment. Recognizing the shortage of overload safety in contactors, you need to strategically incorporate different protecting units to mitigate any undue stress that would culminate in tools injury. Be aware that your selections immediately impression the operational integrity and security of industrial management methods.

Key Takeaways

- Perceive the perform and limitations of management contactors inside motor management eventualities.

- Acknowledge the dangers related to contactors with out overload safety for electrical tools.

- Implement various security measures in industrial management for complete circuit administration.

- Be certain that electrical management methods are outfitted with the required protecting units.

- Change into aware of the dynamics between inrush present administration and extended overload safety.

- Admire the significance of strategic industrial management design in enhancing system security and tools longevity.

Understanding the Fundamentals of Contactors and Electrical Management

Greedy the necessities of contactors for industrial management units the muse for strong electrical methods administration. As you discover this basic facet, you will uncover the dynamics of inrush present and overcurrent circumstances, and the indispensable function of overload safety in contactors.

Defining Inrush Present and Overcurrent Situations

When an electrical motor begins, it quickly attracts a excessive quantity of electrical present often called inrush present. This surge, if not mitigated, could cause undue stress and potential injury to your electrical system. Equally, overcurrent circumstances like brief circuits demand speedy consideration as they pose a major danger, resulting in thermal and mechanical injury.

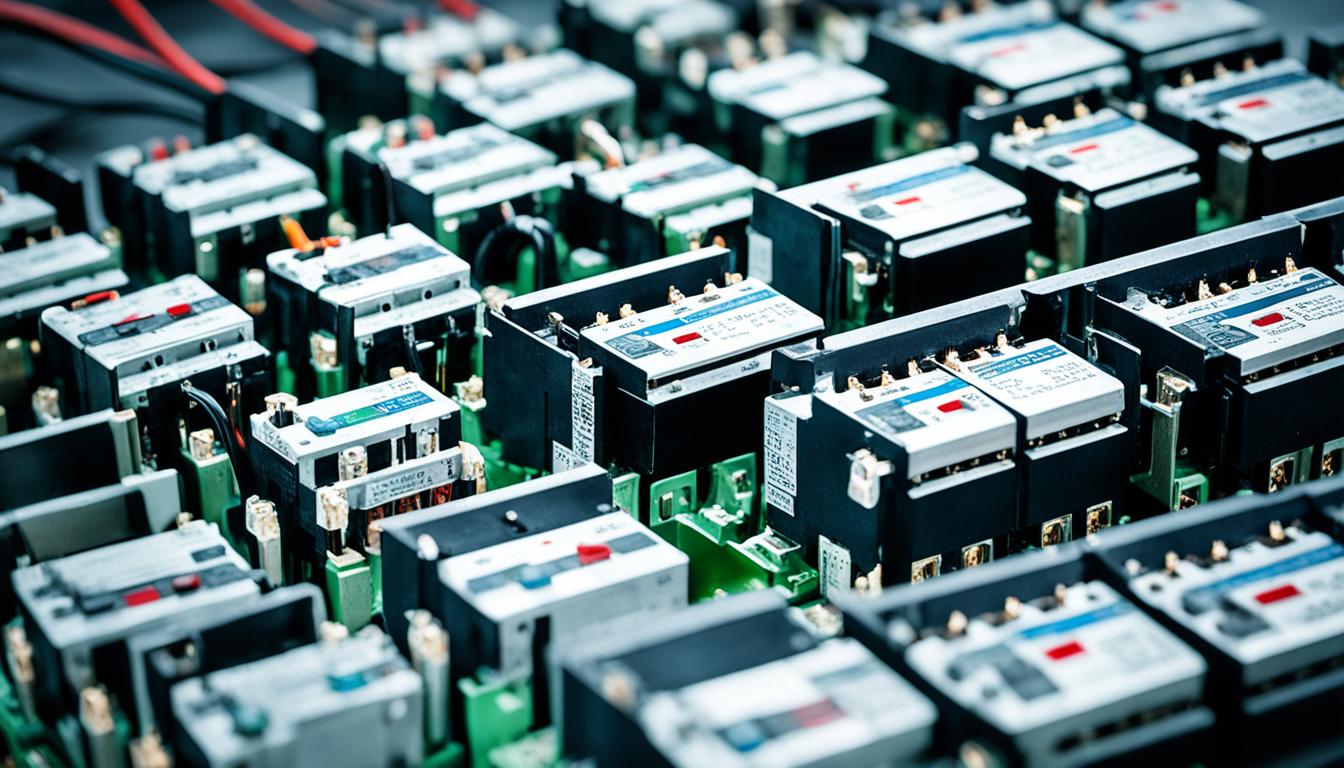

How Contactors Work together with Electrical Tools

Within the realm of circuit safety, contactors act like switches, controlling energy provide to motors and different elements. By cohesively integrating together with your electrical tools, contactors be certain that energy is safely managed, although they don’t inherently present overload safety.

The Function and Necessity of Overload Safety

With out the security web of overload safety, contactors are incomplete. They require extra methods resembling overload relays to protect in opposition to persistent overcurrent circumstances. This integration ensures that your electrical methods preserve operational integrity, optimizing each security and tools lifespan.

Contactors With out Overload Safety Might Be Used To Management?

Within the realm of business management, the utilization of contactors with out overload safety performs a major function. These elements, important for the environment friendly and secure operation of electrical methods, are notably advantageous when a separate overload provision is built-in into the design, or in circumstances the place it is thought-about superfluous. Let’s delve into the economic purposes and advantages of those important management units.

Industrial Management Purposes

Relating to industrial management, the purposes for contactors with out overload safety are huge and assorted. From lighting circuits to heating methods, these contactors are a linchpin for managing energy distribution and management. They’re particularly prevalent in controlling small motors, the place the character of the gadget doesn’t name for built-in safety.

Appropriate Units for Management by Contactors With out Overload Safety

The selection to make use of contactors for controlling electrical tools needs to be knowledgeable by the character of the gadget and its operational setting. Beneath is a desk outlining the sorts of units generally managed by contactors with out overload safety.

| Machine Kind | Software | Overload Safety Wanted? |

|---|---|---|

| Lights | Lighting circuits in business buildings | No |

| Heating Components | Temperature management in industrial settings | Probably, will depend on system design |

| Small Motors | Conveyor methods, small machine instruments | No, if separate safety is supplied |

Benefits of Using Naked Contactors in Circuit Management

Using controlling with out overload safety presents distinct benefits. The simplicity and cost-effectiveness of those contactors make them an interesting selection in a spread of purposes. Nevertheless, it’s crucial that security measures are in place to handle overload circumstances, making certain the longevity and reliability of the managed units.

- Value Discount: With out the necessity for built-in overload safety, these contactors are extra economical.

- Simplicity in Design: Simplifying design complexity results in simpler upkeep and troubleshooting.

- Flexibility: Offers flexibility in configuring management structure with separate protecting units as wanted.

An Introduction to Motor Management and Security

When integrating motors into industrial and business tools, it is paramount to understand the rules of motor management and security protocols. Not solely does correct motor management streamline operation and effectivity, however it additionally underscores the significance of security in controlling electrical tools. Let’s delve into the distinct sorts of motors generally encountered and the essential function of overload safety in preserving each the equipment and the personnel dealing with them.

Integration of Motors into Industrial and Business Tools

As you immerse your self on the earth {of electrical} tools, you will discover that your operational effectivity hinges on the seamless integration of motor management methods. These methods function the nucleus of assorted purposes, dictating the efficiency of motors in numerous units. Starting from conveyor belts in a producing plant to the HVAC methods in business buildings, motor management is an invisible but indispensable drive propelling these machines.

Variations Amongst Single-Part and Three-Part Induction Motors

Key to understanding motor management is recognizing the variations between single-phase and three-phase induction motors. Whereas single-phase induction motors are lauded for his or her simplicity and are sometimes utilized in family home equipment, three-phase induction motors are the workhorses behind the heavy equipment in industrial settings due to their excessive energy output and unwavering reliability.

Overload Safety: Stopping Motor Harm and Making certain Security

Safety in motor operation goes past simply operational protocols; it deeply includes the mixing of overload safety mechanisms. Overload safety shields motors from the risks of extreme present that may trigger overheating and catastrophic injury. Overload relays are the sentinels on this state of affairs, promptly disconnecting the ability to avert potential hazards. Thanks to those units, you’ll be able to belief the longevity and environment friendly operation of your motors, making certain your operational tempo by no means misses a beat.

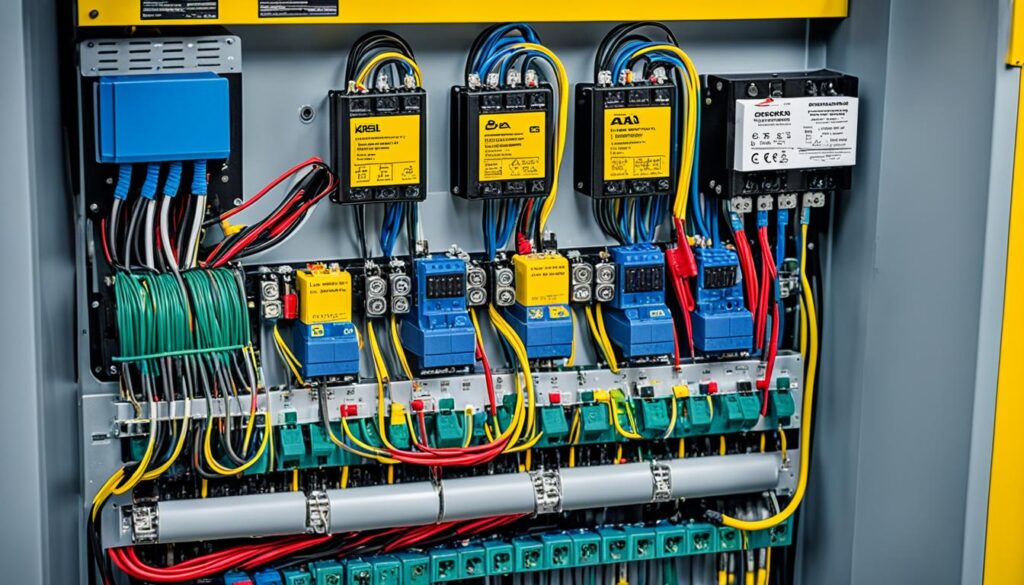

Significance of Circuit Safety for Secure Operation

Making certain the security {of electrical} methods largely hinges on strong circuit safety. A crucial element of this safety is the safeguard in opposition to brief circuits, a typical but probably devastating electrical fault. The swift motion of fuses and different overcurrent protecting units is vital to sustaining security and stopping injury to each tools and personnel.

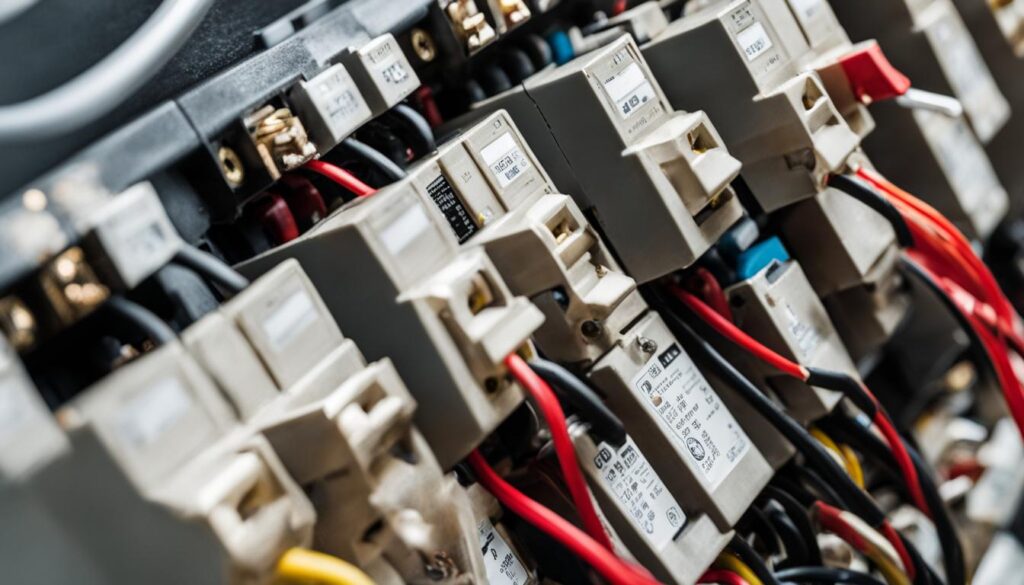

Brief Circuits and Fuses: A Important Prevention Measure

Brief circuits could cause vital injury to electrical methods as a result of sudden escalation in present move. That is the place fuses play an indispensable function. Designed to be the weakest hyperlink in {an electrical} circuit, fuses soften and interrupt the present when a fault, resembling a brief circuit or overload, causes a sudden surge of excessive present, successfully stopping additional injury.

Analyzing the Function of Overcurrent Protecting Units

Overcurrent from brief circuits or overloads can lead to catastrophic failures. Therefore, quite a lot of overcurrent protecting units, together with circuit breakers and overload relays, are integral to any electrical set up. Their principal perform is to detect extreme present move and to disconnect {the electrical} load from the availability, making certain the integrity and longevity of the system.

Contactors in Trade: Varieties and Security Concerns

Within the realm of business management, the choice of contactors is essential. Numerous sorts exist, tailor-made for various purposes. When selecting contactors for industrial management, take into account their voltage ranking, current-carrying capability, and skill to interrupt a circuit underneath load. These specs are important security issues that safety contactors can effectively handle the calls for put upon them.

- Steady responsibility ranking – ensures the contactor can deal with the system’s common operational present with out overheating.

- Interrupting capability – the utmost fault present the contactor can safely interrupt, an crucial function for stopping tools injury.

- Voltage ranking – aligns with the system’s voltage stage to keep away from arcing and potential electrical fires.

Your vigilance in making use of correct circuit safety and deciding on applicable contactors ensures the security and resilience of business management methods in opposition to the dangers {of electrical} faults.

Conclusion

Within the huge panorama of electrical management, the function of contactors with out overload safety is simple. These contactors are the linchpins in a mess of industrial management purposes, offering an simple and economical choice for managing energy distribution and management inside subtle electrical methods. Nevertheless, the absence of built-in overload safety means you need to keenly devise and implement a community of circuit safety units to make sure the enduring security and operational integrity of motor-driven equipment.

As somebody liable for the design or upkeep of those methods, comprehending the synergy between contactors, motor management models, and protecting units resembling fuses and overload relays is crucial. Certainly, the success of electrical methods hinges not simply on their particular person elements, however on the strategic layering of safeguards they embody. A sturdy method to circuit safety invariably prevents pricey failures and minimizes potential downtimes, thereby bolstering productiveness and reliability.

Bear in mind, your command over these parts—the contactors with out overload safety, the protecting units, and the electrical management methodologies—dictates how successfully and securely your methods function. By making certain that every of those important elements is chosen, utilized, and maintained with precision, you fortify the pillars of business equipment and drive the engines of business ahead with assurance and effectivity. Controlling with out overload safety does not must be a vulnerability—it may be a strategic benefit, when underpinned by appropriate circuit safety measures.

FAQ

What are contactors with out overload safety used to regulate?

Contactors with out overload safety are used to regulate numerous electrical units like lights, heating parts, and sure motors in industrial management purposes, the place separate overload measures are supplied or not required.

Why is inrush present vital when discussing contactors and electrical management?

Inrush present or locked rotor present is vital because it represents the massive surge of present a motor attracts upon startup. Correct administration of this inrush present by contactors is essential to keep away from disturbances and potential injury to {the electrical} system.

What function does overload safety play along side contactors?

Overload safety safeguards electrical methods from the gradual improve in present as a result of extreme load, which contactors alone don’t deal with. Usually, separate overload relays are paired with contactors to offer this safety.

What are some benefits of utilizing contactors with out built-in overload safety?

The primary benefits embody decrease price and the simplicity of design. Additionally, utilizing naked contactors permits for the flexibleness of implementing guide or separate computerized overload safety primarily based on the precise wants of the set up.

How are three-phase and single-phase induction motors dissimilar?, and why is that this vital for motor management?

Three-phase induction motors differ from single-phase motors of their building and operation technique, which depends on electromagnetic induction. They’ve larger effectivity and energy functionality, making overload safety for these motors notably vital for secure and dependable operation.

Why are brief circuits and fuses crucial within the context of secure electrical operation?

Brief circuits could cause sudden, substantial will increase in present resulting in potential injury or fireplace dangers. Fuses act as a fast-acting preventative measure by interrupting the move of extra present, thereby providing crucial safety.

How does one collateral the security of contactors utilized in industrial management methods?

To make sure secure operation, it’s critical to decide on contactors with the suitable voltage, continuous-duty, and interrupting capability rankings for the system’s electrical calls for. It is also essential to include correct circuit safety units to stop injury from overcurrent and brief circuits.